Materials

All HSK - DIN 69893 F Toolholders are made of case-hardened steel. The supply of the material, made by the main Italian steel mills, is accompanied by the 3.1 UNI EN 10204 certifications.

Thermal treatments

A carburization is carried out with a depth of 0.4 - 0.5 mm in order to achieve a value of HRC hardness of 58 ± 2 and a tensile strength of 800-1000 N / mm2.

Grinding

After the burnishing, the parts are grinded externally and internally, including the threads of the nuts that tighten the collet.

Quality

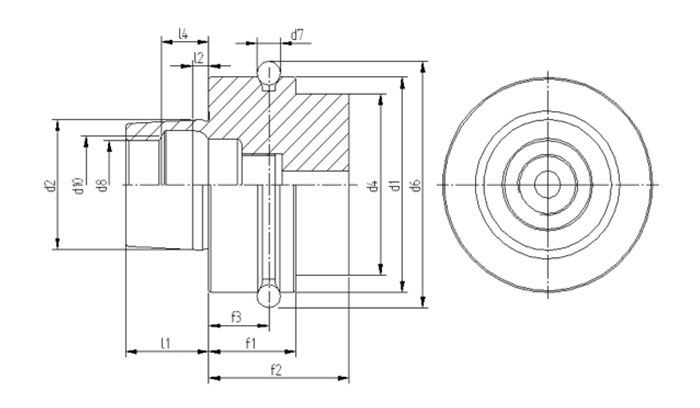

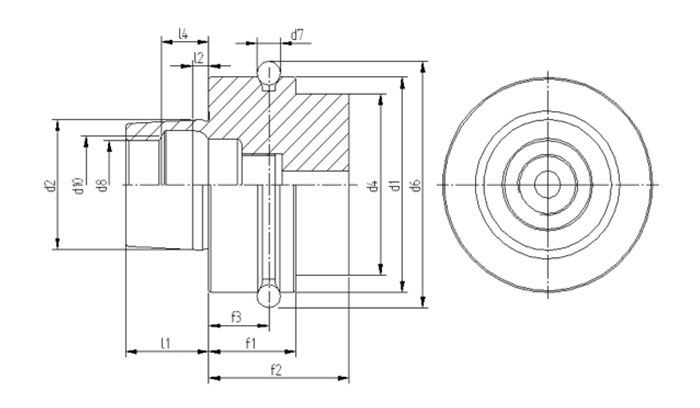

Technical details of the cone

|

HSK 50 |

HSK 63 |

| d1 |

50 |

63 |

| d2 |

30 |

38 |

| d4 |

42 |

53 |

| d6 |

59,3 |

72,3 |

| d7 |

7 |

7 |

| d8 |

21 |

26 |

| d10 |

23 |

29 |

| f1 |

26 |

26 |

| f2 |

42 |

42 |

| f3 |

18 |

18 |

| l1 |

20 |

25 |

| l2 |

4 |

5 |

| l4 |

11,42 |

14,13 |

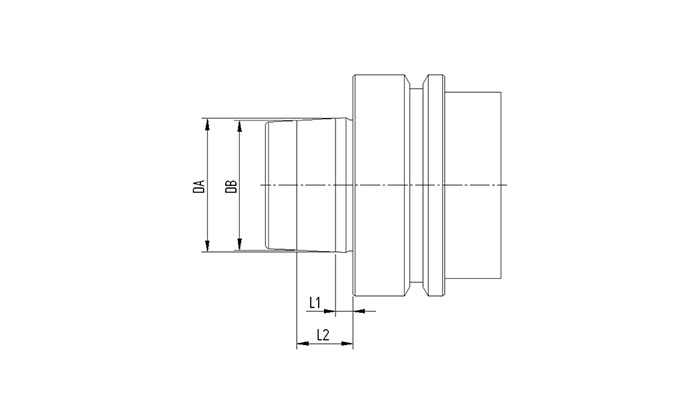

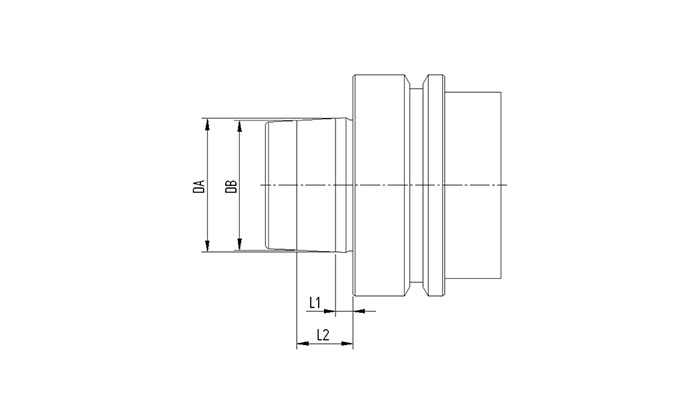

Tolerance of the cone

The taper complies to DIN standards according to the following table:

| HSK |

L1 |

L2 |

D.A. |

D.B. |

| 32 A |

3,2 |

7,3 |

24

|

23,27

|

| 40 A+E |

4 |

9,5 |

30

|

29,05

|

| 50 A+E |

5 |

11 |

38

|

36,9

|

| 50 F |

4 |

9,5 |

30

|

29,05

|

| 63 A+E |

6,3 |

14,7 |

48

|

46,53

|

| 63 F |

5 |

11 |

38

|

36,9

|

| 100 A |

10 |

24 |

75

|

72,6

|

|

Features and use

Central collant supply possible through coolant tube.

With larger collar.

Used for high frequency spindles and wood machining.

Balancing

In accordance with company's internal quality procedures, Toolholders are pre-balanced in class G 6,3 a 8000 rpm for 1 min. balancing is performed almost for each toolholder of this product family, using Haimer Balancing Machines up to the class G1 at 40000 rpm for 1 min.

Coaxiality

Collet Chucks

Parts are produced according to DIN69882-6, that allows a maximum runout deviation of 0.005 mm for DIN6499 Collet Chucks

Shell End Mill Adaptors

All Toolholders meet the requirements of the DIN69882-2 standard, that allows a coaxiality of 0,01 for Ø 16-22-27-32.

Weldon / Whistle Notch End Mill Holders

In compliance with DIN 69882-4, the hole is made in tolerance class H5, with an average coaxiality value of 0.005 mm

Quality of production

We perform accurate tests on 100% of our production through certified instrumentation:

- Certified taper control, by calibrated gauges

- Checking of threads and seats with taper clamps and collet holder, with MG Calibri gauges

Quality Pagnoni

Produzione